Aramco’s market-ready Converge® polyols answer consumer demand

Aramco Performance Materials (APM) returned this year to North America’s Foam Expo in March with market-ready carbon dioxide (CO2) polyols.

Since its public debut last year, APM has attracted significant interest from major U.S. and global polyurethane manufacturers, as well as fabricators and end-users looking for strong product performance with improved sustainability features.

A new kind of polyols

Polyols are not new. However, these are not conventional polyols. APM has been able to differentiate itself in the marketplace by creating them in an entirely new way.

APM uses a proprietary catalyst that takes waste CO2 as a main feedstock and combines it with propylene oxide to create a poly (propylene carbonate) polyol — a high performance polyurethane building block with a reduced carbon footprint.

During the opening day of the conference, APM president Peter Shepard updated attendees on Converge® technology and product advances in a panel discussion titled “Evaluating Developments in the Polycarbonate (CO2) Polyols Market for the Polyurethane Industry.” Shepard said CO2 feedstock is a trend that will become common practice.

“Consumers are demanding that sustainable materials be incorporated into end-products,” said Shepard. “Industry is responding by turning waste CO2 into profitable, commercially viable opportunities — not only in polymers and polyols, but in chemicals, as well as other sectors such as fuels.”

Showcasing Converge® technology

Panelists discussed topics such as market trends and the impact on the polyurethane foam industry, how regulations can promote the adoption of this technology, and the next steps in innovations incorporating sustainable CO2-based polyols.

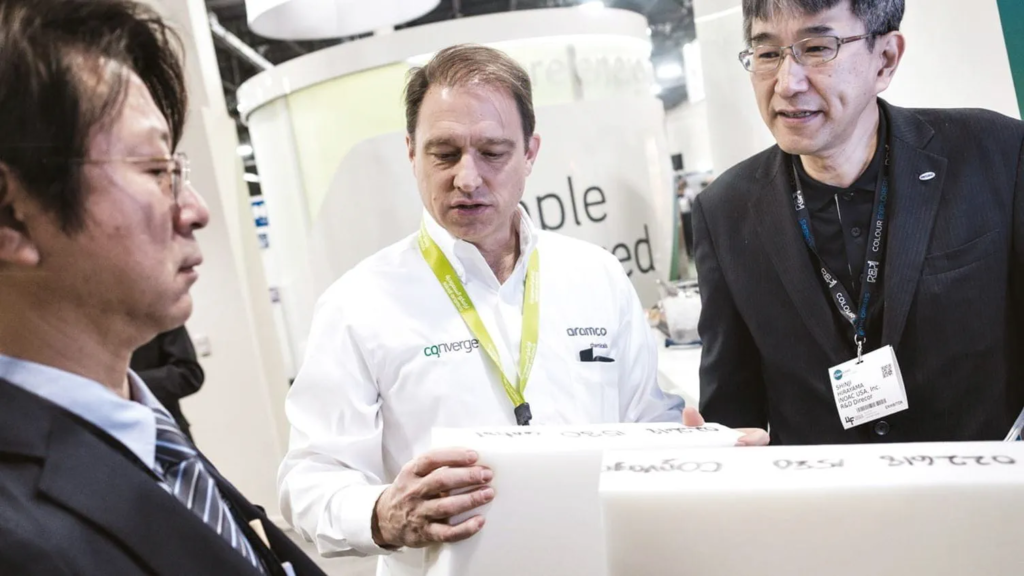

Abdullah AlYahya, APM Commercial director, described Foam Expo as a great platform to showcase Converge® technology.

“We had steady traffic from current and potential customers in a variety of market segments such as automotive and furniture, and they all had one common goal — enhanced performance,” said AlYahya.

A dinner event with potential customers highlighted the performance advantages of Converge® products in flexible and rigid foams. The event provided a great opportunity to hear directly from customers and understand the limitations they face today when using conventional polyols.

AlYahya said customers are searching for solutions to their unmet needs and are viewing Converge® technology as a unique solution and a way to differentiate their products in the future.

Aramco Performance Materials (APM)

Exhibition visitors learned about advances APM has made in furthering product performance characteristics such as load bearing strength, reduced noise vibration, and harshness in a number of different foam applications. In the past year, APM has also been supporting new specialized applications for customers and refining its Converge® manufacturing processes.

Michael Nagridge, the APM Global Technical Services manager who focuses on bringing the technology to many applications and assisting customers developing new Converge® applications, brought foam samples recently produced in commercial scale customer trials. These samples demonstrated the durability, cushioning, and/or isolation from noise and vibration benefits Converge® technology brings to end-products in the foam industry.

APM has made advances in validating its products with customers in a number of applications, including flexible foam, rigid insulation foam for construction, industrial use, and appliances, as well as for coatings, adhesives, sealants, and elastomers.

This second year of the conference doubled in size, with more than 3,000 people attending and Aramco generating more than 150 new customer leads. Aramco served as one of the conference sponsors, heightening its visibility in the conference program and mobile app.

Converge® illustrates Aramco’s continued commitment to chemicals innovation and expanding beyond commodity-based chemicals to value-added products and chemistry.

Email: info@cyber-gear.com

Email: info@cyber-gear.com